In Best Power Practices I we discussed a variety of issues related to properly powering your gear. We covered the need for dedicated power wiring as well as the desirability of using standard connectors.

Power Wire Gauge

We previously discussed the need to utilize wire of the proper gauge for feeding power to our radios, and also the fact that conventional vehicles do not have wiring from the factory capable of carrying the current required for a typical mobile amateur radio. Utilizing that wiring will likely result in damage to the wiring over time.

So, you've decided to properly power your rig with dedicated wiring for your gear. But what kind? Certainly you want to use stranded wire in a mobile rig, as solid wire eventually suffers from the vibration of the vehicle and will become damaged over time. Stranded wire is also more flexible and tolerate of being routed through the vehicle. The insulation type is important, particularly in automotive applications, where temperatures (even in the cabin) can be quite high. Cross-Linked polyethylene (XLP), and Polyvinyl Chloride (PVC) will do the job, but plain polyethylene will break down at temperatures in the cabin, much less in the engine compartment.

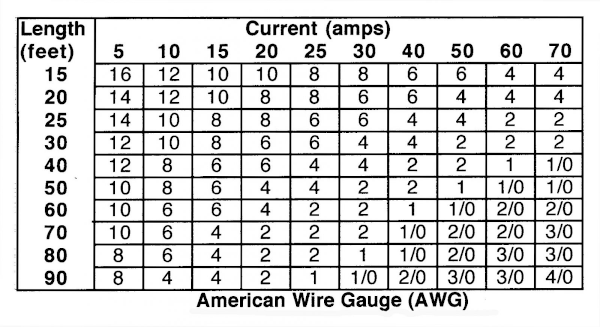

As important as the above considerations are, one must carefully consider the wire gauge, which is dictated by the amount of current you want to draw and the distance to be covered. Generally speaking you'll want to double the length you'll run, since you'll be dropping voltage across the hot and ground leg. The chart below will be useful for determining gauge. In most cases you'll find 10AWG will do the job for typical 2-meter 50W rig and possibly for a 100W HF rig if the run is short enough (otherwise 8AWG would be better). As amps needed and length of wire run goes up, the gauge size will be lower. Always keep your wire runs as short as possible.

Solid Connections

Don't scrimp on making your electrical connections. The finest and heaviest gauge wire you can install will serve little purpose if the connections between the battery and the radio are poorly made. Remember, you aren't just hooking the radio up to work today, you're hooking it up so it still works flawlessly five years later. Every connection and component between your power source and your radio adds resistance and voltage drop, requiring the radio to pull more current to make up for the lost voltage, so you want to ensure your connections are clean, solid, and not between two metals that will react with each other. If at all possible, your wiring should go from power source, immediately to fusing, and then to the radio connector, minimizing in-line resistance.

In mobile installations you'll want to connect the hot lead to the battery and, whenever possible, the ground lead to the same point on the chassis the battery is grounded. Electrically, that point is the best "compromise" between the battery's ground and the alternator's ground, minimizing ground-loop effect. If wiring to the battery/chassis junction is impractical, then get as close as you can.

Speaking of solid connections, poor electrical connections can cause significant RFI issues, so if you've checked your antenna, coax, & connectors and are still getting RFI, engine noise on your transmitted signals, and other such odd things, give your wiring a good looking at! Keep in mind, a little RFI from a mag-mount antenna is almost inevitable.

Fusing

Contrary to what many believe, fuses do not exist to protect your radio, the exist to protect your wiring and avoid a fire that could burn down your home or leave your vehicle a smoldering heap on the side of the road. Improperly connected radios will likely be destroyed by high current before it occurs for the fuse to blow. Remember, your radio will pull 10-20 amps on transmit, so if you've improperly connected the radio 20 Amps will flow through it endlessly. Worse yet, a 20 amp fuse will pull 30 amps for well over a minute, and 100 amps for almost two seconds. This is why it is a really good idea to use keyed and color coded connectors and wire whenever possible.

You may have noticed that many rigs come with two fuses, one for the hot and the other for the ground leg. This seems a bit redundant on the surface, but many engineers believe it is a necessary protective precaution. It is believed that in the event of a ground interruption there will be high current through the negative lead and the fuse will blow during high current draw (when you're transmitting). The gear in my car is dual fused, but I actually have a problem with the concept. If the ground fuse should blow (for whatever reason), the typical mobile radio will find a path to ground through the antenna coax, which is not designed to handle high current. There's even a chance the radio would appear to function normally (at least for a while) until the coax is damaged or the ground loop damages the radio.